In the field of heat provision, we aim to tap regenerative—mainly solar and geothermal—heat sources.

Our research approach ranges from the development and optimisation of individual components to their integration into complex energy systems. The field also includes the development of highly efficient thermal insulation.

Our work focuses on:

Contact:

This joint project with a total of eight project partners, funded by the Federal Ministry for Economic Affairs and Energy, deals with quality improvement in shallow geothermal systems. Building on knowledge gained in the preceding project QEWS II, important aspects from design and planning to execution and commissioning are being investigated to solve any problems that may arise. Four sub-projects address thermal testing methods, TRT testing equipment, backfill materials, and modelling, with multiple project partners contributing their expertise in each.

ZAE's contribution to the project is the development of an in-situ measurement and evaluation procedure that allows for testing and determination of geothermal source systems' thermal-energetic properties. Also, the thermal response test (TRT) method is to be made available for other source systems besides borehole heat exchangers in order to characterise thermal behaviour in the subsurface and improve design calculations. The existing testing unit for TRT devices is set to be further developed and then to be used in establishing certification rules for such devices. Moreover, the quality of various backfill materials will be further investigated with particular regard to freeze-thaw cycles, ways to improve them will be sought.

The project's overall goal is ensuring and enhancing the quality of near-surface geothermal systems. This is to reduce risks, lower the cost of energy production, increase the efficiency and availability of plants, and increase the public awareness for and acceptance of near-surface geothermal systems.

Head of Project: Peter Osgyan, peter.osgyan@zae-bayern.de

Project Duration: 01/2021–12/2023

Website: https://www.quewsplus.de

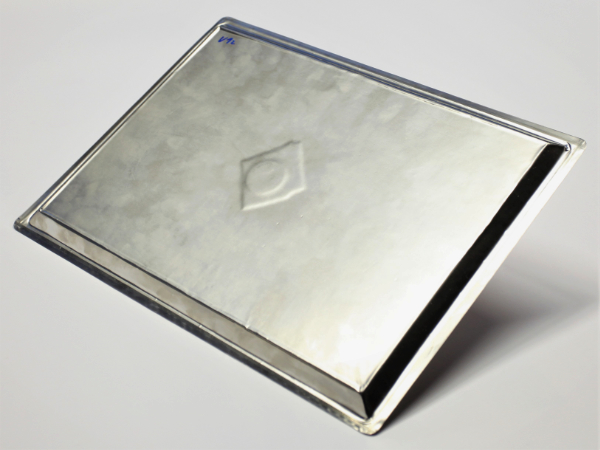

A large share of Germany's primary energy consumption goes into high-temperature processes (200 to 1.000 °C) in energy-intensive industries (e.g. metal, glass). Despite thermal insulation and heat recovery, however, high thermal losses are a common issue. To increase energy efficiency in industrial processes, this project aims to develop a highly efficient high-temperature thermal insulation using vacuum super insulation (VSI). The functional principle of VSI revolves around the evacuation of porous powder materials (fumed silica, expanded perlite) to suppress gaseous heat conduction. By compacting the powders into sheets and wrapping them in a vacuum-tight film, flat vacuum insulation panels (VIPs) can be fabricated. The main area of application for high-temperature VIPs in this project is in mobile, containerised solid-state heat storage systems operating at storage temperatures of 200 to 600 °C. These will be insulated with high-temperature VIPs to improve their heat storage efficiency and make better use of energy-intensive industries' high waste heat potential, both internally and externally (district heating).

Head of Project: Peter Osgyan, peter.osgyan@zae-bayern.de

Project Duration: 12/2018–05/2022

If necessary, critical outdoor traffic areas in Germany are usually directly heated through electricity. The use of ground-coupled heat pumps however, which are also already in use for this purpose, is far more efficient. Using the directly coupled CO2 geothermal probe technology, which relies solely on geothermal energy, even eliminates the need for additional energy to drive pumps or a compressor. This saves conventionally generated energy and thus cuts CO2 emissions.

The aim of the planned project is to open up a much broader field of application for this technology and establish the required basic principles. Within the project, the first task will be to work out questions about the heat transfer in CO2 thermosiphons and surface heating elements and to develop prototypes based on the findings, which will then undergo laboratory testing. Simultaneously, the necessary software for designing such systems will be developed. Finally, two demonstrators will be equipped with the technology and monitored metrologically.

Head of Project: Lars Staudacher, lars.staudacher@zae-bayern.de

Project Duration: 06/2019–05/2022